Alkaline Zinc

Alkaline Zinc

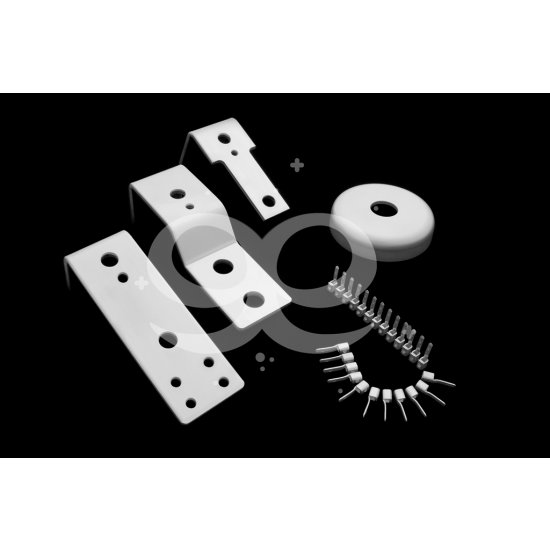

The coating plate obtained through the alkaline zinc coating process is smooth and shiny. The coat layer exhibits a perfect distribution.

•Excellent wrapping power and metal distribution

•Extremely bright and ductile coating with low stresses

•High levels of thickness, applicability on hardened steel

•Faster coating process, High Anti-Corrosive Properties and Brightness resulting in a perfect coating that resembles an excellent passivation.

Passivation layer thickness ranging from 0.1 to 1.0 µm

•Contains 100% Cr+3

•Good wear resistance

•High thermal resistance

•Balanced yellowish/ silvery colour, a self-improving layer, high corrosion resistance and UV resistance.

*Yellow passivation procedures applicable on customer requests on the finished coat surfaces.

•Top coat preserves the chromate layer and is resistant against thermal shocks.

Top coat: A specially formulated organo-mineral liquid concentration developed to cope up with the increasing corrosion demands of the car-making industry, in coatings with electrolysed zinc and alloys. Can provide protection against corrosion for up to 480 hours for white rust formation.